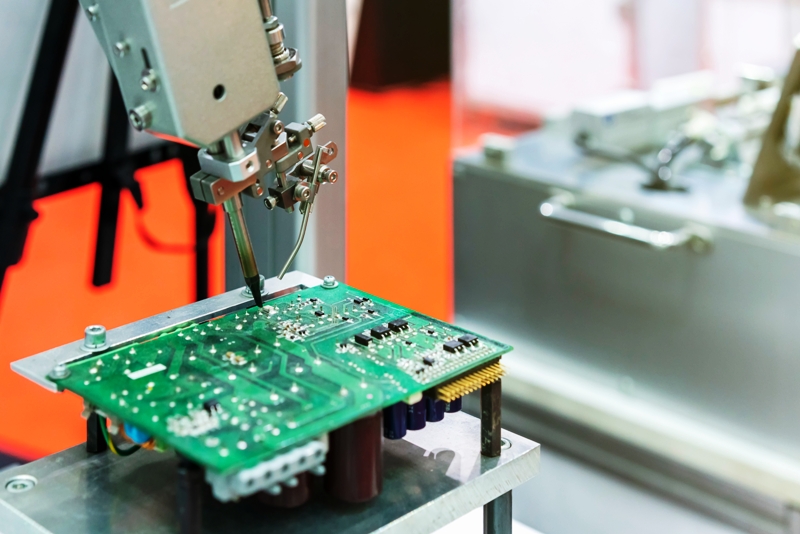

Precision engineering plays a vital role in the electronics industry, particularly in the realm of Printed Circuit Board (PCB) assembly. PCB assembly technology has evolved significantly over the years, enabling manufacturers to achieve unparalleled levels of precision and accuracy in the assembly process. This precision engineering is essential for unlocking the full potential of PCB assembly technology and realizing the myriad benefits it offers.One of the primary benefits of precision engineering in pcb assembly is the ability to achieve high-density component placement. With advancements in technology such as Surface Mount Technology (SMT) and microelectronics, manufacturers can place electronic components with extreme precision and accuracy, even in tight spaces. This high-density component placement allows for the creation of smaller and more compact electronic devices without sacrificing functionality or performance.

Whether it’s a smartphone, smartwatch, or IoT device, precision-engineered PCB assembly enables manufacturers to push the boundaries of miniaturization and create products that are both sleek and powerful.Moreover, precision engineering ensures optimal soldering and connection quality. Soldering is a critical aspect of PCB assembly, as it involves joining electronic components to the PCB substrate to create functional circuits. With precision engineering techniques such as automated solder paste dispensing and reflow soldering, manufacturers can achieve consistent and reliable solder joints with minimal defects. This ensures robust connections that withstand various environmental factors such as temperature fluctuations, vibrations, and mechanical stress, enhancing the overall reliability and durability of electronic devices.

Furthermore, precision engineering enables advanced quality control and inspection processes. With technologies such as Automated Optical Inspection (AOI) and X-ray inspection, manufacturers can thoroughly inspect PCBs for defects, anomalies, and soldering issues with unparalleled precision and accuracy. This ensures that only high-quality, defect-free PCBs make it to the final assembly stage, minimizing the risk of costly rework or product recalls. Additionally, precision-engineered inspection processes enable manufacturers to identify and address potential issues early in the production process, ensuring the highest level of quality and reliability in electronic devices.

Precision engineering drives innovation and customization in pcb assembly. With the ability to achieve precise component placement, soldering, and inspection, manufacturers can explore new design possibilities and push the boundaries of what’s possible in electronic device design. Whether it’s integrating advanced features, improving performance, or reducing power consumption, precision-engineered PCB assembly enables manufacturers to tailor electronic devices to meet the specific needs and preferences of consumers, driving innovation and differentiation in the marketplace.From high-density component placement and optimal soldering quality to advanced quality control and customization capabilities, precision-engineered PCB assembly enables manufacturers to create innovative, reliable, and high-performance electronic devices that meet the demands of today’s consumers. By leveraging the power of precision engineering, manufacturers can drive innovation, improve product quality, and stay ahead of the competition in the fast-paced world of electronics.